- Waste management

Here is how paper waste is recycled?

Collection, transportation, and storage:

The most difficult task for paper recycling companies is probably the collection, transporting, and sorting of waste paper.

It is because we always add paper waste to other waste items and get them contaminated with food, plastics, and metals.

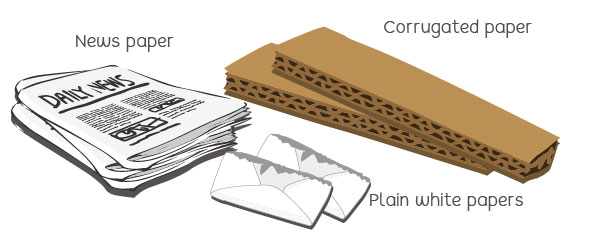

Sometimes collected paper is sent back to the landfills because they are too contaminated for use. Try to keep waste paper in separate grades at home or in the office —for example, do not mix newspapers and corrugated boxes up.

All paper recovered is sent to the recycling center, where they are packed, graded, put into bales, and sent to the paper mill. At the mill, all the paper is stored in a warehouse until it is needed.

Repulping and Screening (say re-pal-pin and skree-nin):

From the storage shelves, they are moved into a big paper-grinding machine called a vat (pulper). Here the paper is chopped into tiny pieces, mixed with water and chemicals, and heated up to break it down into organic plant material called fiber. After, it is screened to remove contaminants such as bits of plastic and globs of glue.

Deinking (say dee-in-kin):

It involves washing the pulp with chemicals to remove printing ink and glue residue. Sometimes, a process called floatation is applied to further remove stubborn stains and stickies. Floatation involves the use of chemicals and air to create bubbles that absorb the stickies in the pulp.

Refining, Bleaching, and Color Stripping:

Refining involves beating the recycled pulp to make them ideal for paper-making. After refining, additional chemicals are added to remove any dyes from the paper. It is then bleached to whiten and brighten it up.

Paper-making:

At this stage, the pulp is ready to be used for paper. Sometimes new pulp (virgin pulp) is added to give it extra strength and smoothness. Water is added to the pulp and sprayed onto a large metal screen in continuous mode. The water is drained on the screen and the fibers begin to bond with each other. As it moves through the paper-making machines, press rollers squeeze out more water, heat them dry and coat them up.

They are then finished into rolls.